- Home

- Products

- Stress Measurement

- Polarized Stress Measurement

Stress Measurement

Polarized Stress Measurement

Experts in Polarized Stress Measurement

i-Boson Technology leads in polarized stress measurement, utilizing advanced optical designs and precise data analysis tools. We specialize in solving stress detection challenges across various industries. Our innovative technology helps clients achieve more efficient and accurate measurement results.

.png)

High-Resolution Polarized Images

Capture internal stress distributions within materials using birefringence phenomena, generating clear polarized images and achieving precise measurements of stress magnitude and direction.

.png)

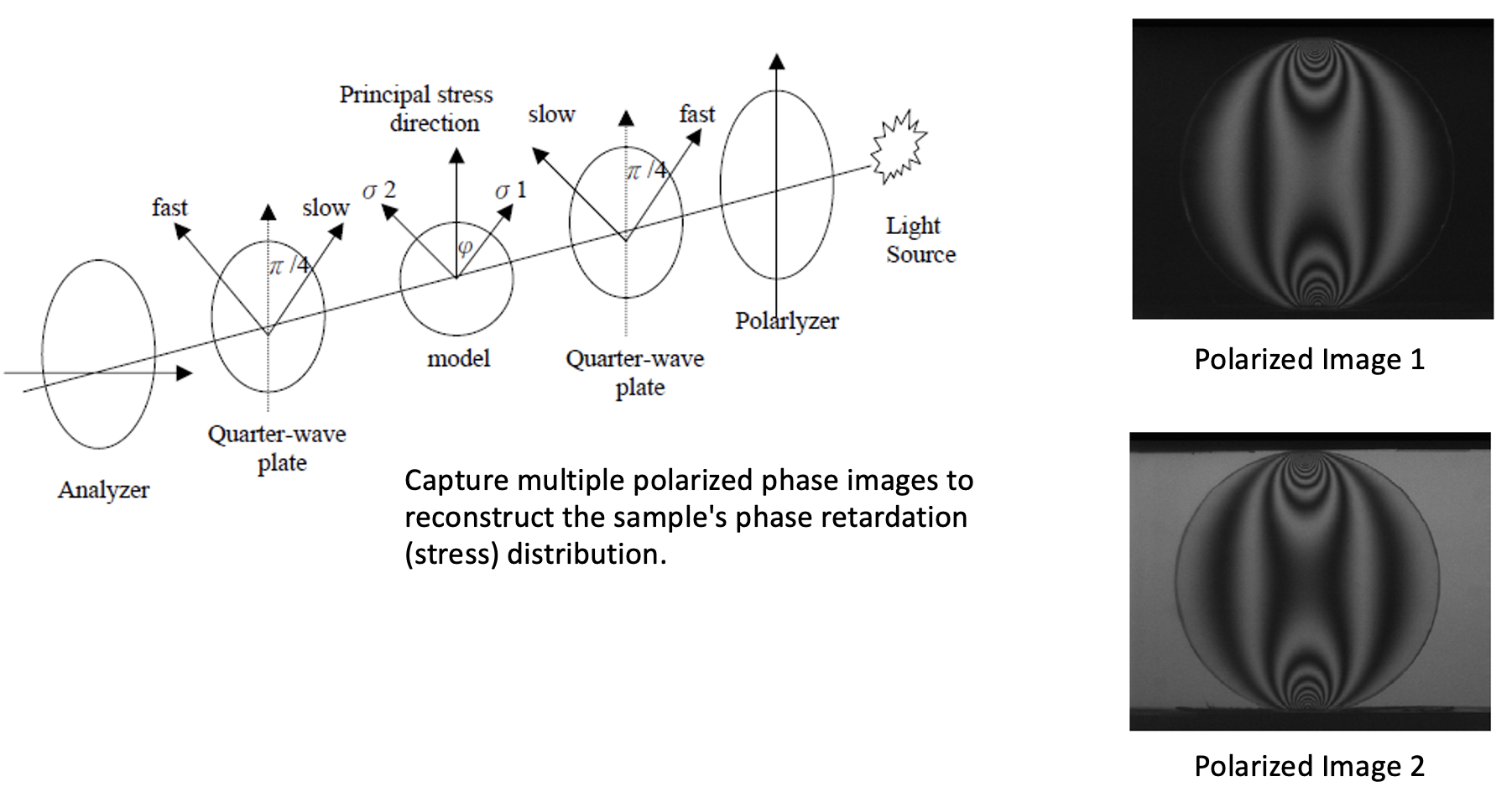

Phase Retardation Measurement

Utilize multi-phase polarized image analysis techniques to reconstruct phase retardation distributions within materials, providing highly sensitive stress detection solutions.

.png)

Automotive Substrate Stress Measurement

Provide stress detection services for glass substrates and PMMA injection-molded structures, solving manufacturing quality issues in automotive components.

.png)

TGV Process Stress Distribution

Analyze TGV process stress using high-precision polarized imaging technology, ensuring structural stability and material strength.

Why Choose i-Boson Technology?

- ✔ Adoption of advanced birefringence analysis technology for accurate stress measurement results.

- ✔ Support for large-scale and low-stress material detection, flexibly meeting diverse needs.

- ✔ Built-in efficient data algorithms for intuitive stress distribution visualization, enhancing decision-making efficiency.

- ✔ Trusted by industry leaders like Apple, TPK, and Innolux.

Product Introduction

Large-Scale Stress Measurement

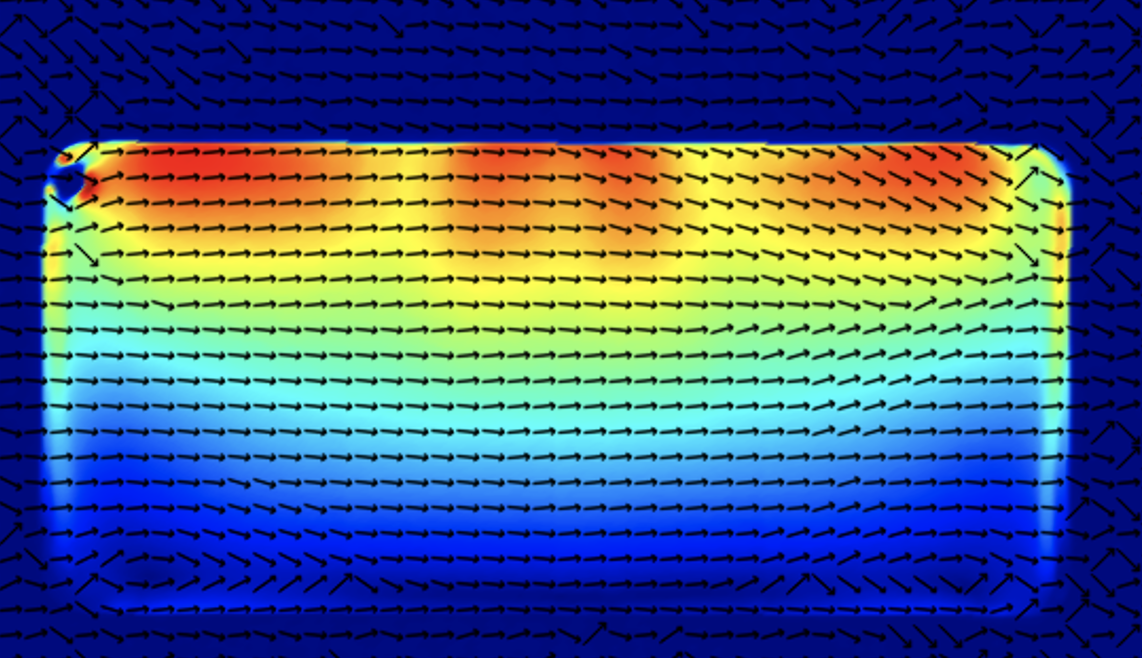

Utilizing high-sensitivity global stress measurement systems, suitable for detecting stress in large-area materials or structures. By combining multiple polarized images to reconstruct phase retardation distributions, we can accurately measure stress direction and magnitude, particularly applicable to glass, flexible electronics, and solar cell stress measurements.

- Rapid large-area measurement

- High reproducibility, suitable for comparative testing

- Applications include glass cutting stress detection and flexible displays

Large-Scale Low-Stress Measurement

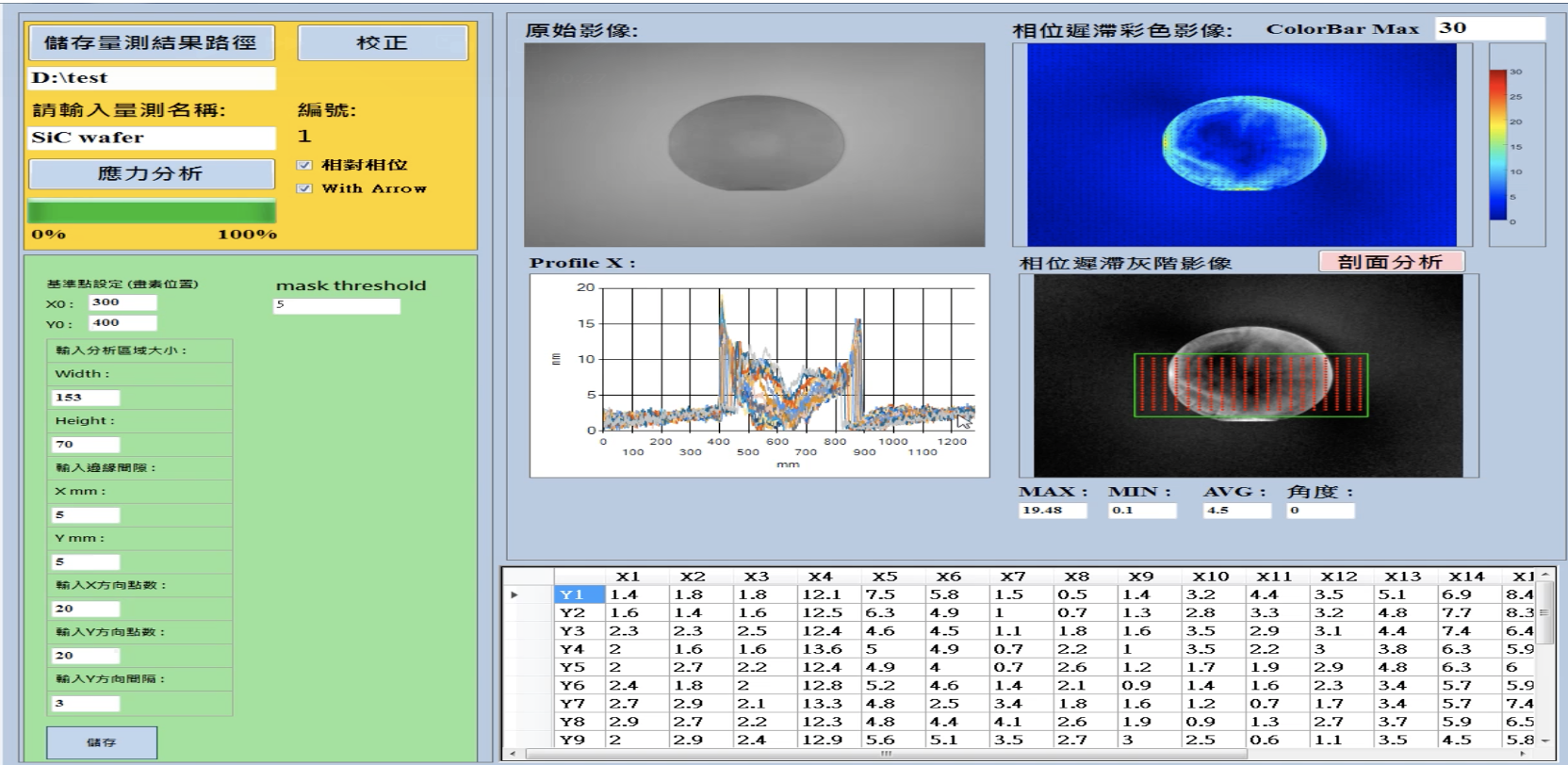

Designed specifically for low-stress detection, this system employs optimized optical structures and algorithms to precisely analyze minimal residual stress within materials. This module is suitable for in-depth analysis of stress distribution and birefringence effects in transparent wafers, silicon carbide, and other sensitive materials.

- Focused on low-stress detection with high sensitivity

- Capable of eliminating background stress interference to ensure accurate results

- Applications include TGV process stress analysis and PMMA material inspection

Technical Advantages

i-Boson Technology leverages advanced polarized stress measurement techniques, combining high-precision equipment and data analysis tools to help various industries achieve efficient and accurate stress detection solutions.

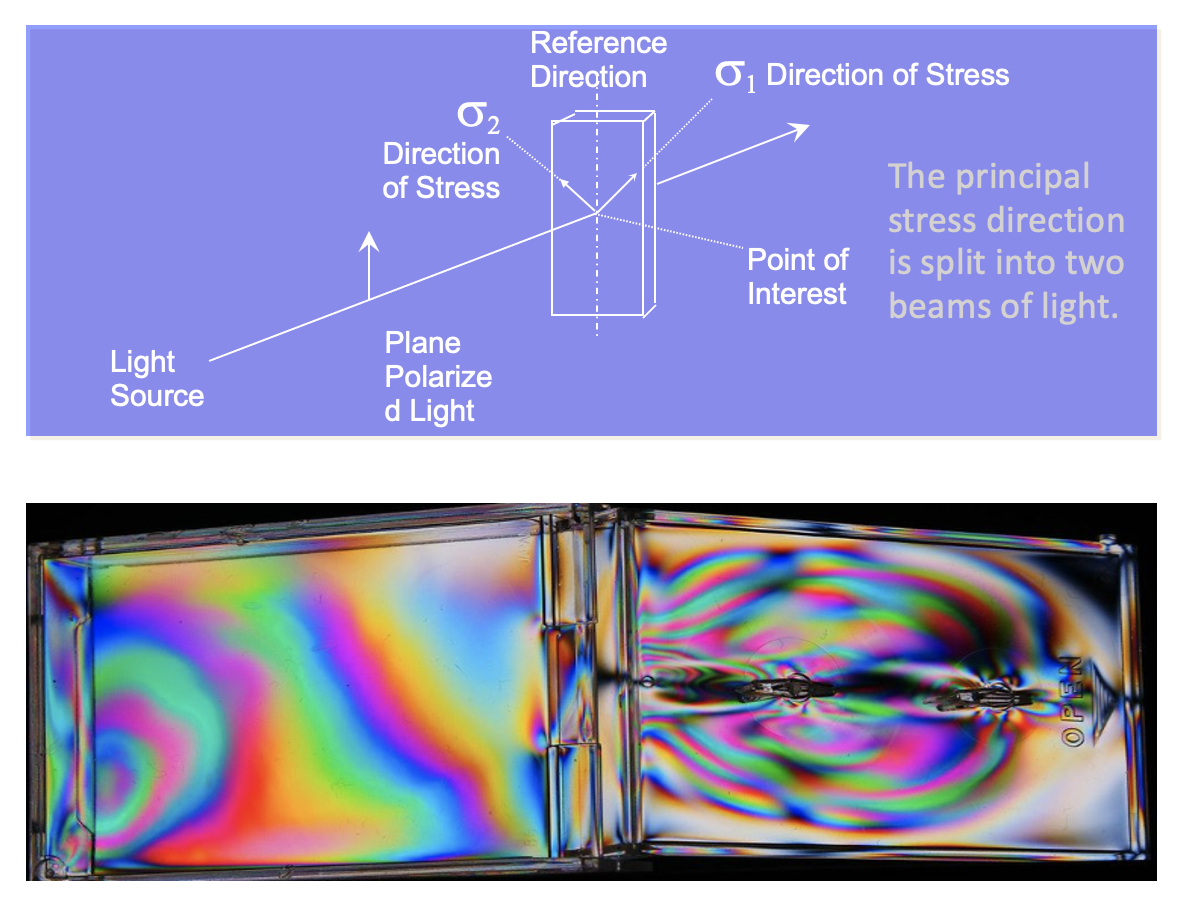

Principle of Birefringence

Using the phenomenon of birefringence, the internal stress in materials is decomposed into two polarized directions, accurately presenting stress direction and magnitude. This is the core technology for inspecting transparent and semi-transparent materials.

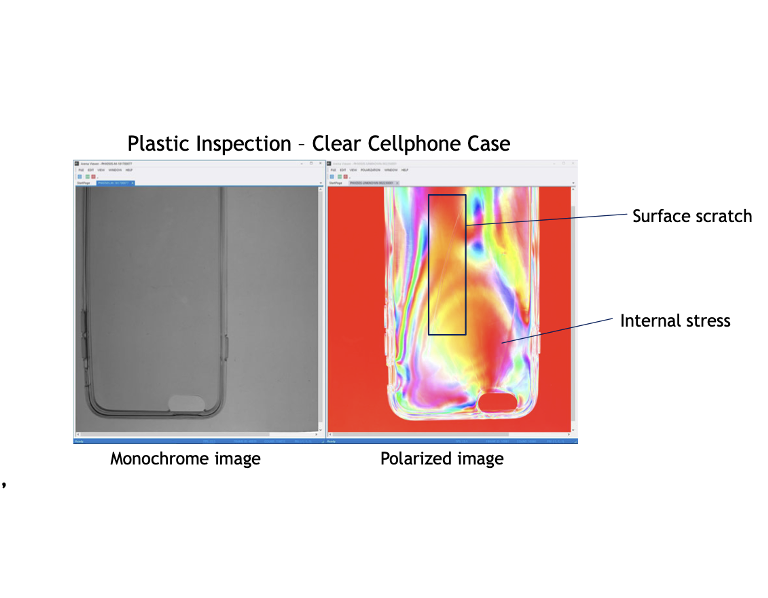

High-Precision Photoelastic Imaging

Utilizing polarized image technology, stress distribution and photoelastic effect data are reconstructed. This technique is applicable to detecting internal stress and surface defects, such as in transparent plastic phone cases or precision optical components.

Multi-Phase Image Reconstruction

By collecting multiple polarized images and using phase retardation technology, stress distributions are reconstructed to help clients analyze material mechanical properties precisely and improve production yield.

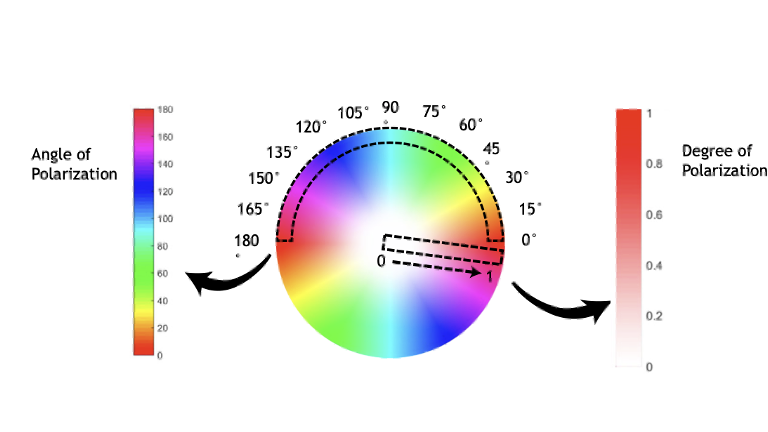

Polarized Data Visualization

Innovative data visualization technology combines polarization angle and degree of polarization maps, providing intuitive analysis of stress distribution and material properties.

Application Scenarios

Glass Manufacturing and Inspection

Polarized stress technology is commonly used to detect whether there is stress concentration inside the glass, preventing cracks or fractures during use and improving product reliability.

Optical Component Manufacturing

In the production of optical lenses or high-precision optical components, this technology is used to detect internal stress, ensuring components have stable optical performance to meet high-end application requirements.

Plastic Product Stress Analysis

Particularly in injection molding, residual stress is detected to improve process quality and effectively reduce defect rates. This is applicable to various plastic material processing.