APPLICATION

- Home

- Application

- Automotive Displays and Lighting

- Display Sparkle Measurements

Sparkle Measurements

No need to pre-photograph reference samples.

High measurement stability and repeatability.

Simultaneously evaluate panel luminance and chromaticity uniformity.

- Measure with BlackMURA compliant equipment and settings.

- Measurements can be made without removing the anti-glare layer.

- Highly relevant to human perception.

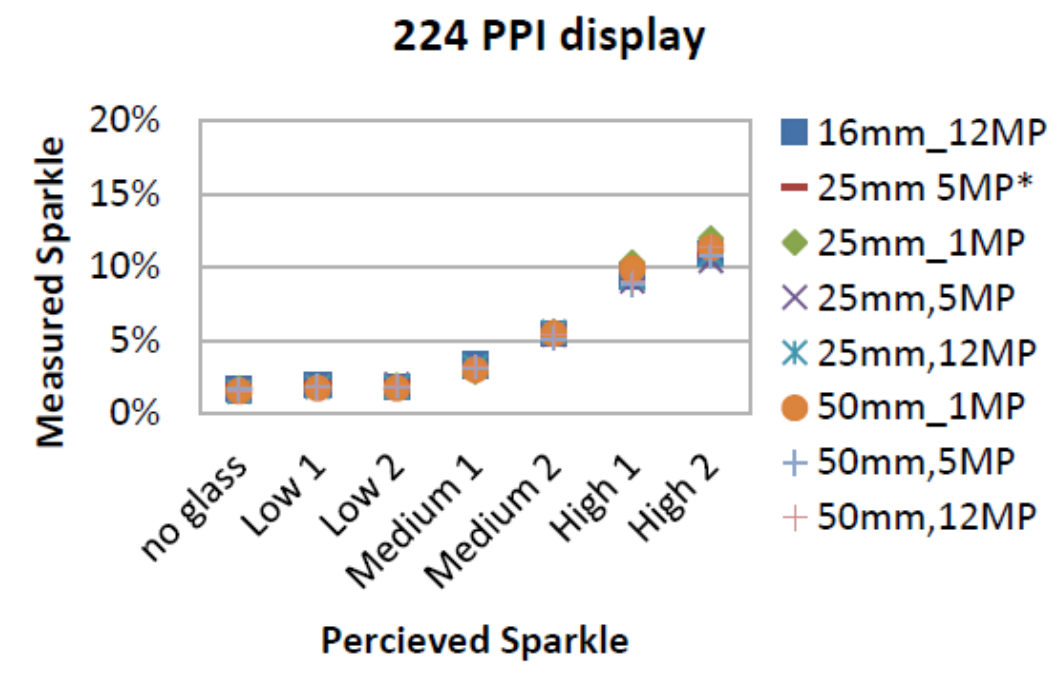

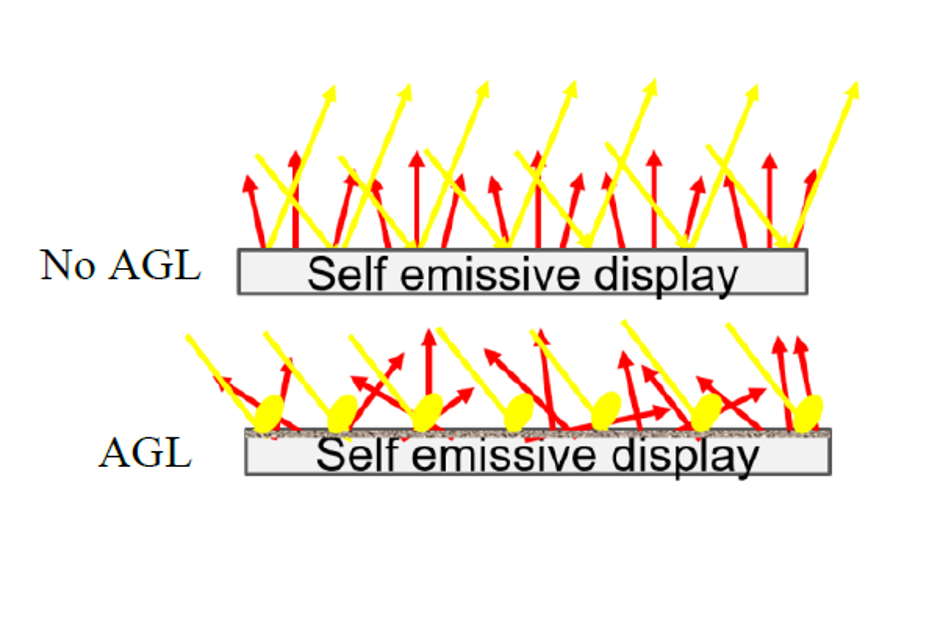

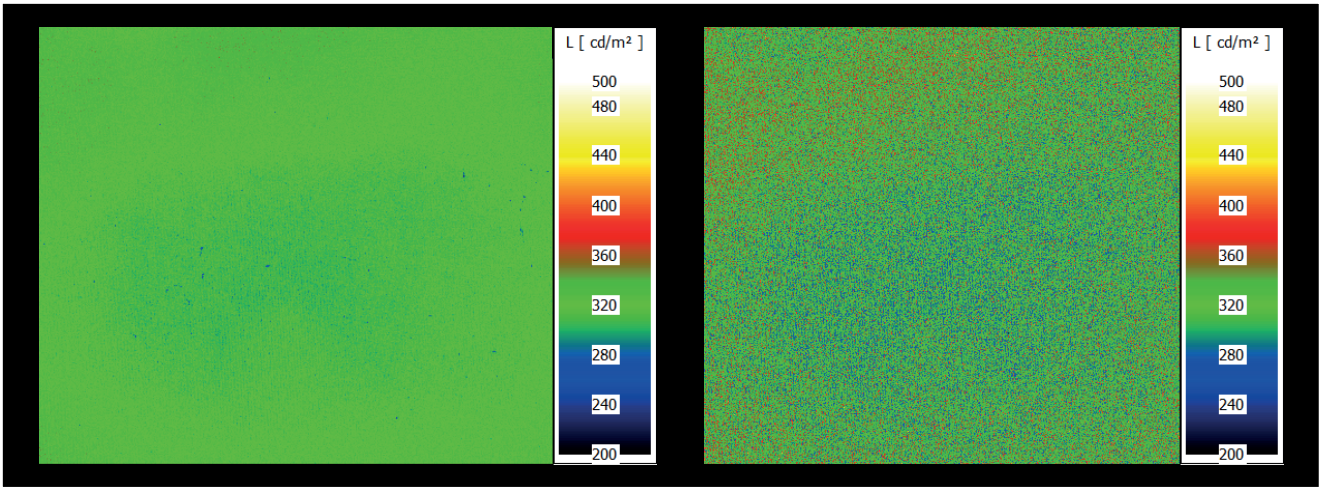

Mobile displays and vehicle displays will be directly exposed to sunlight. In order to avoid glare, anti-glare (AG) treatment will be performed. However, anti-glare treatment can also lead to sparkle effect (Sparkle), which brings bad user experience. For Sparkle's quantitative testing, there is currently no testing specification or standard in the industry that can ensure the reproducibility of testing, so it cannot be effectively promoted in the industry. TechnoTeam GmbH, Volkswagen AG, and Elektrobit Automotive GmbH (a 100% wholly-owned subsidiary of Continental AG) set up a joint task force to conduct a lot of test research work and develop new test conditions and methods for Sparkle test reproducibility. The research results will be Used to formulate new vehicle display test standards.

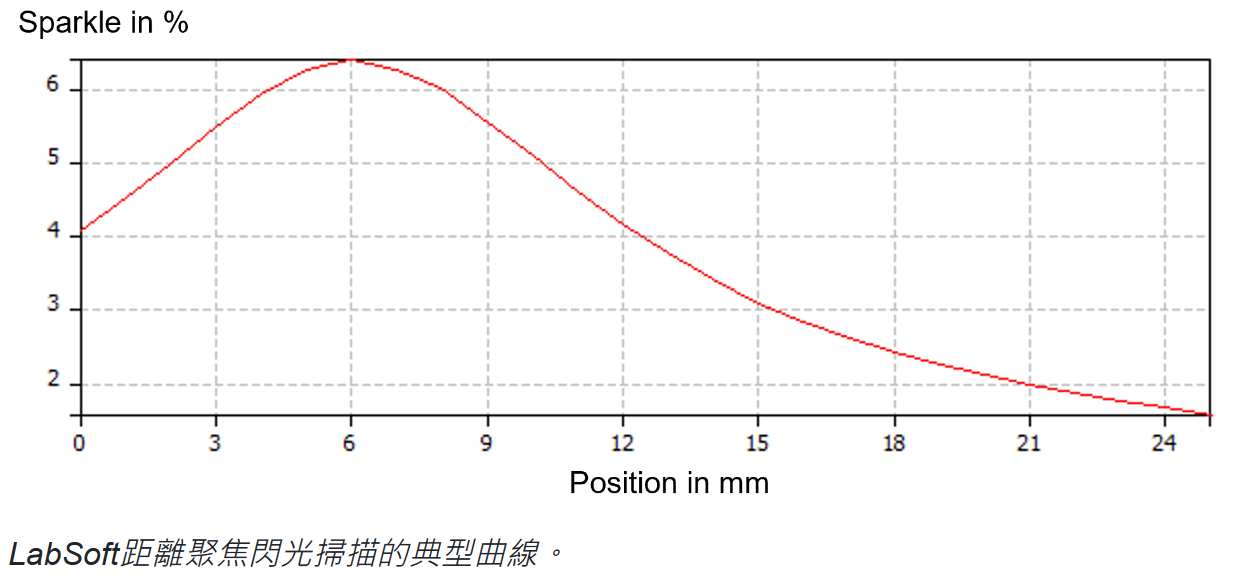

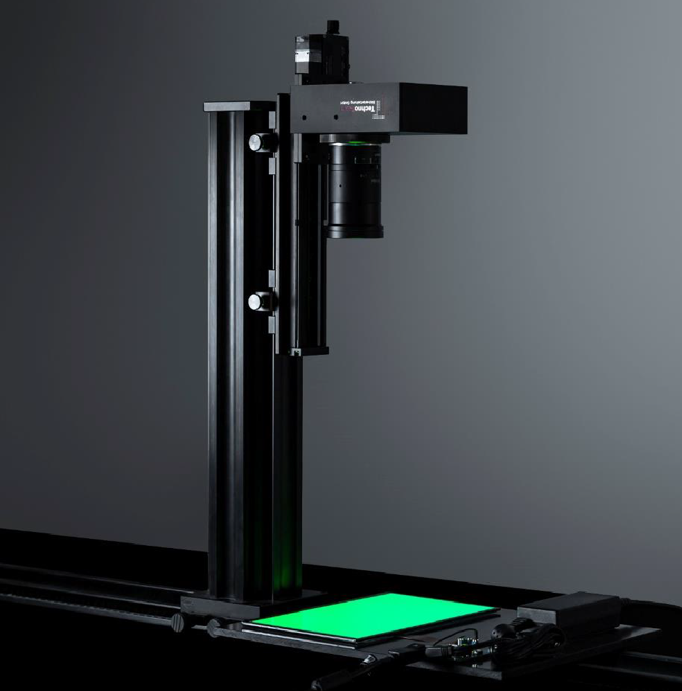

Since the flash value focus setting is very sensitive (blurred flash can be critical), the Techno Team developed the distance focus scan. Using this method, all LMKs (especially manual focus lenses) can be used to search for the maximum where we have the sharpest flash images. This significantly improves reproducibility and ensures that we evaluate the worst-case flashes that humans can observe in samples. All that is required is a simple motorized linear axis, which can be ordered with a flash attachment. Of course, add-ons also allow the use of external (even manual) stages. Alternatively, the LMK Positon system can also be used.