- Home

- Application

- LCD

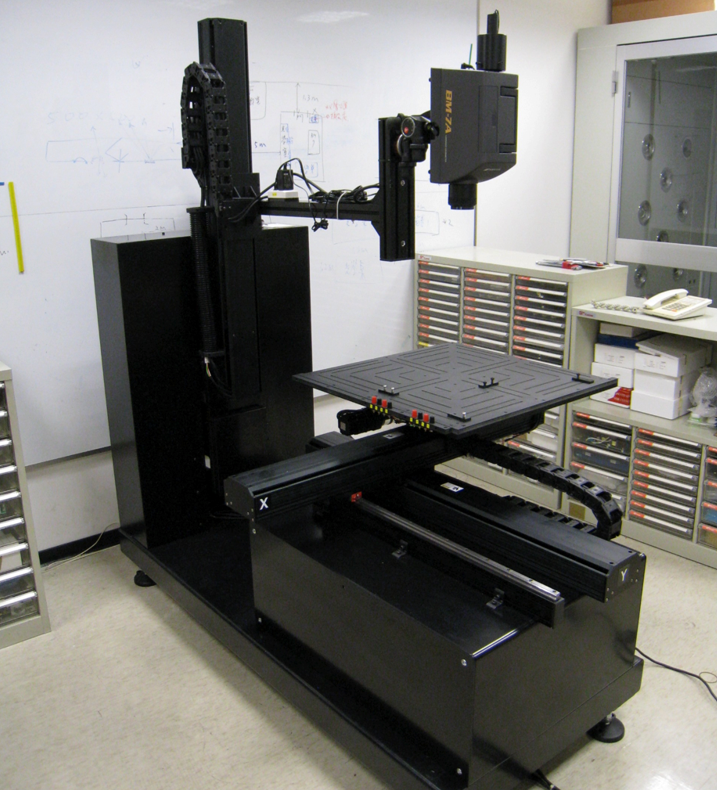

- LCD Quality Inspection System

FP-H5-M

LCD Quality Inspection

The LCD Quality Inspection System FP-H5-M is designed for monitoring product shipping standards and confirming development issues, determining the quality of flat display screens. It offers a highly flexible measurement display system. Its features include multi-axis automatic rotation and movement of fixtures control, brightness meter color brightness measurement control, display screen control, and power supply control.

Furthermore, based on the VESA 2.0 measurement standard specifications, it conducts characteristic measurements to determine the quality of flat panel displays. Currently, various panel manufacturers use BM7, BM5A, SR-3, CS-1000A, CS-200, and other color brightness meters as standard measurement instruments for single-point measurement systems.

To achieve the required measurement points using the color brightness meter, an optical fixture system becomes an essential component of the automated measurement instrument.

Built on the foundation of VESA 2.0 and enriched with the essential flat panel display measurement functionalities for product development:

Configurable automatic measurement of selected items after a designated warm-up time, eliminating the need for personnel to wait.

Luminance, Color Coordinate, and Color Temperature adhere to VESA 302-1, VESA 302-2, VESA 306 (Uniformity) standard specifications. Measurements encompass brightness, color coordinates, and color temperature on a fully white screen. The measurement process involves displaying a full white test screen, with the brightness meter positioned vertically (90°±0.3°) at the preset test points on the specimen (5pts, 9pts, 13pts, 25pts, etc.) for measurement. The measured results focus on the adequacy of center-point brightness and the uniformity of brightness across the specimen.